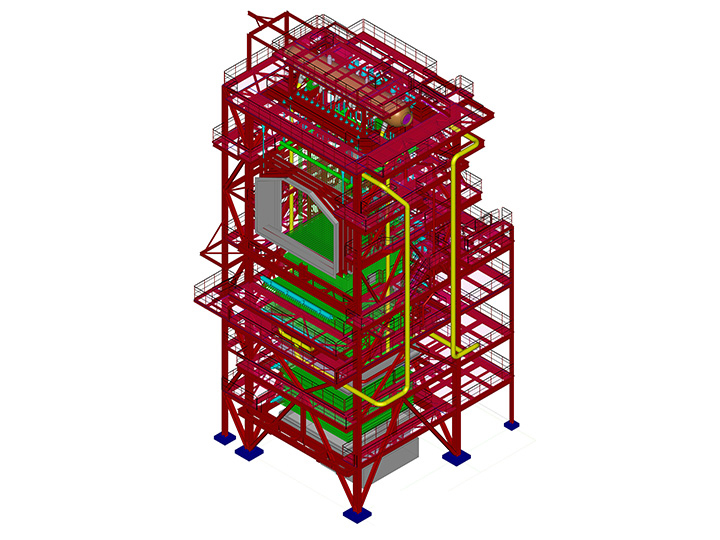

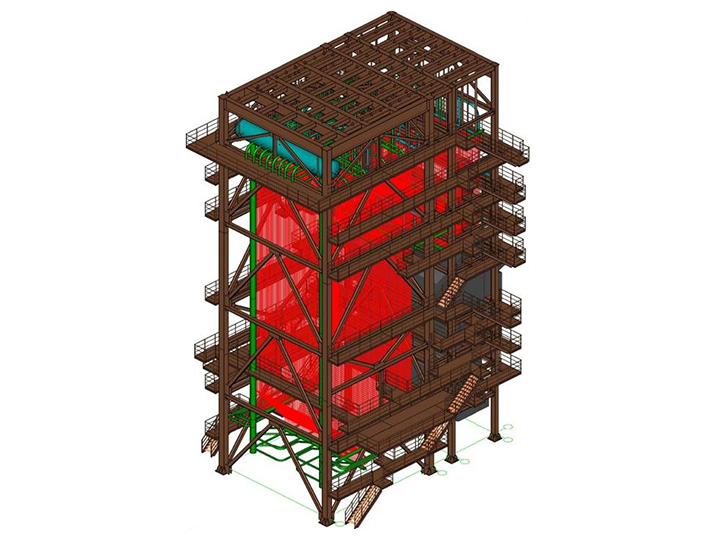

Circulating fluidized bed boiler:

Based on the introduction of circulating fluidized bed boilers researched and developed by domestic research institutes, the company has adopted a variety of proven patented technologies for the technical characteristics of circulating fluidized bed boilers, so that our circulating fluidized bed The boiler has long-term operation, good environmental protection parameters, high boiler efficiency, and wide operating adjustment parameters.

The company's main products:

1. Coal-fired circulating fluidized bed boiler series

Boiler evaporation: 35-480t/h

Boiler steam pressure: 3.82-13.7MPa

Rated steam temperature: 450-540 ° C

Boiler fuel: anthracite, bituminous coal, inferior coal blending, coal gangue, washing coal, slime, etc.

2. Biomass circulating fluidized bed boiler series

Boiler evaporation: 75-220t/h

Boiler steam pressure: 3.82-13.7MPa

Rated steam temperature: 450-540 ° C

Boiler fuel: biomass

3, Circulating fluidized bed hot water boiler series

Boiler heat power: 29-168MW

Boiler working pressure: 1.6MPa

Rated outlet / inlet water temperature: 130-150/70-90 °C

Boiler fuel: anthracite, bituminous coal, inferior coal blending, coal gangue, washing coal, slime, etc.

Boiler features:

a, advanced and efficient large-diameter cooling type high-temperature material separation device to ensure that the separator can adapt to any ash fuel.

b. The full-membrane wall structure ensures the tightness of the furnace, the reasonable size of the combustion chamber, and the low fluidization speed to ensure sufficient fuel combustion and boiler load adjustment margin.

c. Low-temperature combustion technology combined with air classification can significantly control the original emission value of NOx, and can better adapt to increasingly strict environmental protection requirements.

d. Mature and reliable anti-wear structure, combined patented technology of passive anti-wear and active anti-wear, to prevent local wear and reduce overall wear, effectively extending the continuous running time of the boiler and the controllability of maintenance.

e. The biomass boiler adopts a unique multi-flue gas passage and a large pitch structure to solve the problem of high temperature corrosion and low temperature clogging of biomass boilers.

f. The boiler adopts full suspension structure, ∏ type arrangement, coal supply to the front wall and slag discharge at the bottom. Therefore, the overall appearance of the boiler is coordinated and beautiful.

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

Biomass boiler

Biomass boiler  Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler  Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler  Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler